The energy transition in Germany known as the “Energiewende”, is the country’s planned transition from a clear dominance of coal, oil and nuclear to a low-carbon and nuclear-free economy based on the utilization of renewable sources. The ambitious goal is to cut CO2 emissions by 80 Percent and increase the share of renewable energy in total energy consumption to 60 Percent by 2050. Investments in offshore wind, photovoltaics, grid expansion and energy storage projects will be necessary as well as the implementation of a new, smart energy infrastructure that can balance the fluctuating supply of renewable sources. Energy efficiency will play a central role. For decades, Germany has been the global pioneer in applying renewable energy and environmental technologies. However, Germany has maintained a high degree of oil and natural gas to maintain electricity supply security.

Although the share of electricity produced from renewable sources fed into the grid has been constantly increasing, there have been no remarkable incidents of power interruptions thus far. Commercial and private consumers can rely on a stable, continuous energy supply, for Germany has one of the lowest power interruption rates worldwide. (1)

As of June 2020, Germany's hydrogen consumption was approximately 55 terawatt-hours. By 2030, the German government expects hydrogen demand to increase to around 90 to 110 terawatt-hours. Germany's hydrogen demand is the highest in all of Europe. In order to accommodate this demand, electrolysers with a total capacity of up to 5 GW are to be built in Germany by 2030. By 2050, German hydrogen demand is set to grow from the 80 TWh range in 2030 to between 400 TWh and 800 TWh

On 10 June 2020, the Federal Cabinet approved a National Hydrogen Strategy for Germany. The adoption of the final draft now paves the way for 38 domestic measures which will also ensure that Germany plays a pioneering role in the development and export of hydrogen technologies internationally.

In July 2023, the government presented an update to this. The 2020 strategy identified green hydrogen made from renewable electricity as the only sustainable form in the long-term. Other forms of hydrogen are produced from fossil gas – currently the main source – sometimes in connection with capturing CO2 and storing it (CCS). [Find more information on the “colours” of hydrogen here.]

The strategy update says that in order to ensure a rapid ramp-up of the hydrogen market and to meet the expected demand, “other colors of hydrogen will also be used, at least until sufficient green hydrogen is available.” This would especially be low-carbon hydrogen from waste or natural gas in combination with CCS.

The 2023 strategy update defines several targets for the years until 2030:

Not Available

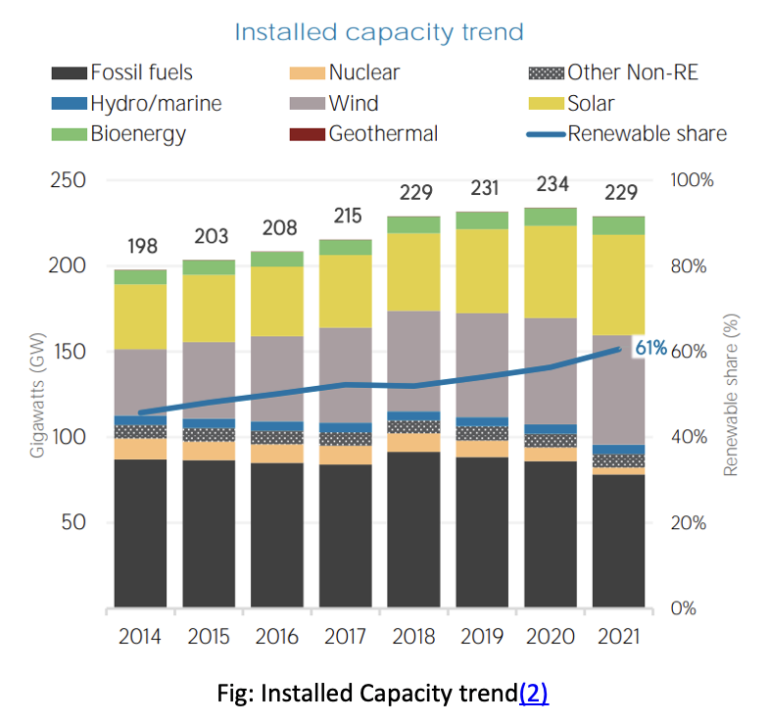

For decades Germany has been the global pioneer in applying renewable energy and environmental technologies. In 2019, 46 Percent of the country's electricity mix came from wind, solar, biomass and hydroelectric sources. That's up 5.6 percentage points over 2018. The bulk of the clean power came from onshore and offshore wind capacity (24.4 Percent), followed by solar (9 Percent) and biomass (8.7 Percent), with the remainder stemming from hydropower. All in all, 238.37 terawatt hours of electricity were generated by all renewable technologies(5) .Preliminary findings sawgross electricity generation from renewables at 238 terawatt hours in 2021. Germany's growing share of green energy will be paramount in the European Union's efforts to reach carbon neutrality by 2050, especially as the EU's largest consumer market struggles to retire its coal plants . (6)

Germany’s electrolyzer portfolio includes the Silyzer product family from Siemens Energy. Using Proton Exchange Membrane (PEM) electrolysis, the Silyzer is ideally suited for harnessing volatile energy generated from wind and solar. Combining high efficiency and high power density, our PEM electrolyzers ensure gas products of superior quality. It is easy to operate and requires low maintenance. Using a modular design strategy that splits the electrolysis system into skids, we are able to optimize costs, reduce installation costs, and make the electrolysis system transportable.(7)